From Design to Compliance: Ensuring Piping Integrity with Stress Analysis

In the demanding oil and gas industry, evaluating the structural integrity of piping systems is crucial for safety, reliability, and regulatory compliance. SPL Global Technologies has assisted leading companies in Malaysia by conducting thorough stress analyses on specialized equipment packages, such as the Steam Desuperheater Package MS-997. Using advanced software like CAESAR II, we assessed the piping system's responses to various loads, ensuring adherence to ASME B31.3 piping code standards. This process results in a comprehensive stress report that supports informed decision-making and operational excellence.

What We Delivered

Our objective was to rigorously evaluate the Steam Desuperheater Package MS-997, focusing on its piping system's structural responses and stresses. Here's what we accomplished:

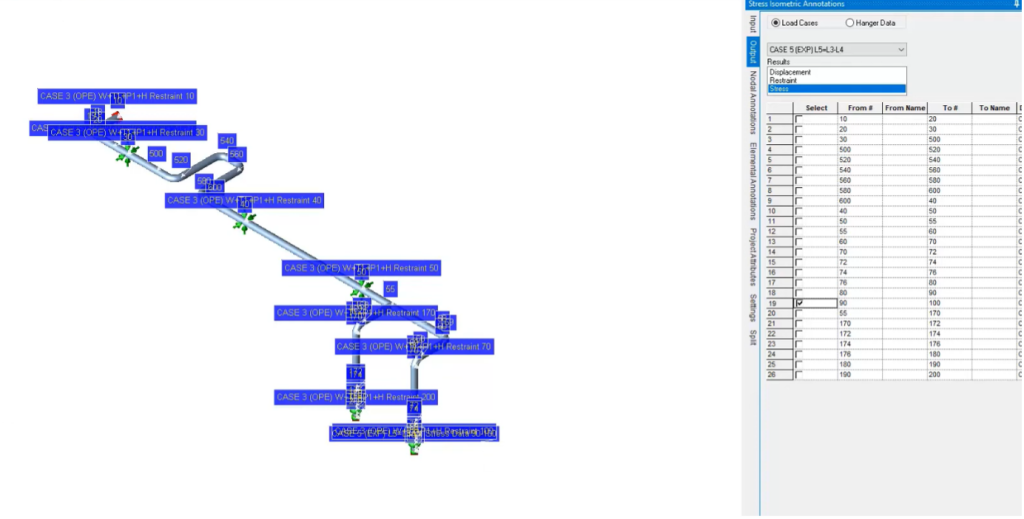

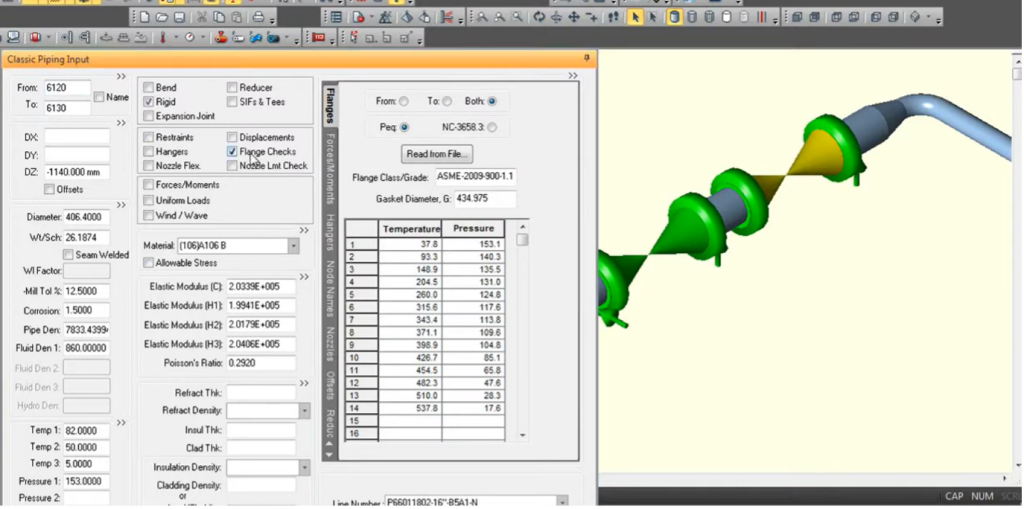

- Modeled Piping System: Built a detailed digital model of the piping system within CAESAR II, incorporating all relevant geometries, materials, and operating conditions.

- Analyzed Structural Responses: Performed dynamic and static analyses to assess responses under thermal, pressure, seismic, and other load cases, identifying potential failure points.

- Stress Evaluation per ASME B31.3: Calculated stresses in accordance with ASME B31.3 code requirements, ensuring compliance with allowable limits for sustained, occasional, and expansion stresses.

- Identified Optimizations: Recommended design modifications or supports to mitigate high-stress areas, enhancing system durability and performance.

- Generated and Submitted Stress Report: Compiled a detailed report with analysis results, visualizations, and compliance verification, ready for client review and regulatory submission.

Our team provided a robust evaluation that not only meets industry standards but also optimizes the package for long-term operational efficiency.

Industry-Leading Tools

We utilized CAESAR II, a software for pipe stress analysis trusted by engineers worldwide. CAESAR II enabled:

- Accurate modeling of complex piping configurations and load combinations.

- Comprehensive stress calculations aligned with ASME B31.3 and other international codes.

- Visualization of stress distributions, deflections, and support reactions through intuitive graphics.

- Automated report generation with detailed outputs for easy interpretation and submission.

CAESAR II's powerful simulation capabilities ensured precise evaluations, minimizing risks and supporting safe plant operations.

Why It Matters

- Enhanced Safety: Identifying and addressing stress hotspots prevents failures, protecting personnel and assets.

- Regulatory Compliance: Full adherence to ASME B31.3 ensures your systems meet global piping standards.

- Operational Efficiency: Optimized designs reduce maintenance needs and extend equipment lifespan.

- Data-Driven Decisions: A detailed stress report provides actionable insights for engineering and procurement.

- Risk Mitigation: Proactive analysis prepares your infrastructure for extreme conditions, from thermal expansions to seismic events.

Why Choose SPL?

SPL Global Technologies is your reliable partner for engineering evaluations and digital solutions. With extensive expertise in CAESAR II and a dedication to precision, we deliver analyses that drive safer and more efficient operations. We don't just evaluate—we empower your projects with compliance and innovation.

Advance Your Engineering with Expert Analysis!

Transform your piping systems into compliant, high-performing assets with SPL Global Technologies. Our stress analysis services boost safety and efficiency while ensuring regulatory adherence. Contact us today to evaluate your next project!