In the fast-moving oil and gas fabrication industry, the accuracy and coordination of material data can define the success of a project. SPL Global Technologies has supported major operators in Malaysia by implementing structured integration workflows between Hexagon Smart Materials (SMAT) and SAP, helping them eliminate manual bottlenecks and establish reliable, traceable, and real-time material management processes.

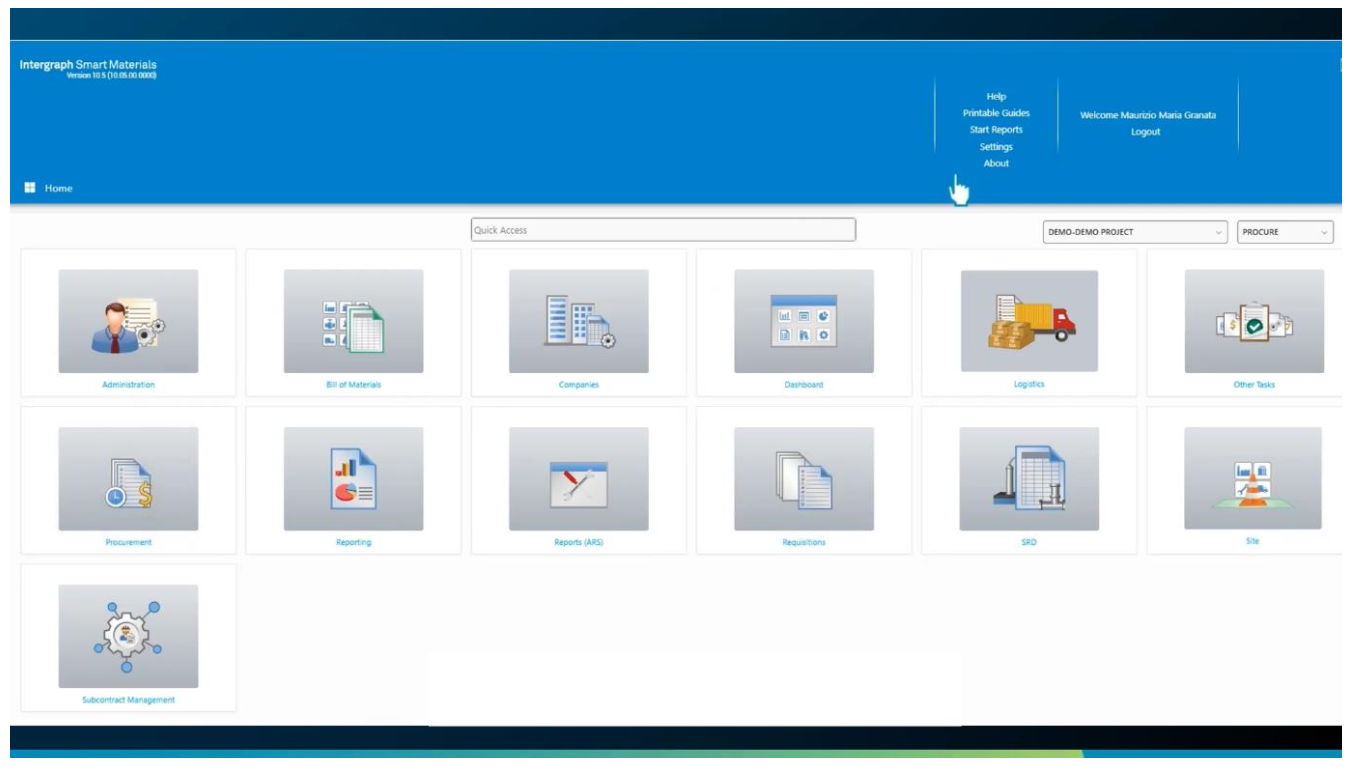

Using deep knowledge of engineering material systems and SAP procurement workflows, we establish end-to-end interfaces that synchronize material codes, purchase documents, and site issuance activities. The result is a unified digital ecosystem that enhances decision-making and operational efficiency across engineering, procurement, and construction teams.

What We Delivered

Our objective was to establish a seamless connection between Smart Materials and SAP, ensuring full data consistency from material creation to issuance at site. Here’s how we achieved it:

• Automated Material Code Synchronization

We configured an interface that aligns material master data between SMAT and SAP. This ensures every material code created by engineering is accurately reflected in SAP, which reducing mismatches and improving traceability.

• Integrated Purchase Requisition (PR) Flow

PRs generated in Smart Materials, whether triggered from BOMs, MTOs, or engineering needs, were automatically transferred into SAP. This streamlined the approval process, minimized human error, and significantly shortened procurement cycle time.

• Real-Time Purchase Order (PO) Updates

All POs raised in SAP were synchronized back into Smart Materials, providing engineering teams with immediate visibility of procurement progress. Amendments and goods receipt updates were also transferred automatically to maintain a complete audit trail.

• Material Issuance & Reservation Synchronization

Material movement and issuance activities performed at the warehouse or fabrication yard in SAP were instantly reflected in Smart Materials. This real-time visibility of stock readiness helps prevent material shortages, over-ordering, and delays during construction.

Our integration solution ensured both systems worked in harmony which supporting efficient planning, better coordination, and faster execution across the project lifecycle.