At SPL Global Technologies, we have had the privilege of working with one of the most renowned oil and gas industry leaders in Malaysia in completing a significant Water Treatment Plant project. We was entrusted with a critical digital enablement role to support the engineering and construction of this vital facility. To ensure project success, we deployed a suite of Smart Enterprise Tools including SmartPlant P&ID (SPPID), SmartPlant Instrumentation (SPI), SmartPlant Electrical (SPEL), Smart 3D (S3D), SmartSketch (SSK), SmartPlant Review (SPR), and SmartPlant Foundation (SPF). In this article, we will share our project experience and highlight our approach which not only cover up software setup for this project, but we also provided user training and business-aligned configuration, along with proactive consulting services to mitigate risks and ensure efficient project delivery.

Strategic Importance of Smart Enterprise Tools

In complex EPC (Engineering, Procurement, Construction) environments, digital tools must do more than just function where they must integrate, educate, and adapt. Smart Enterprise Tools offer robust design integration across disciplines and project phases, ensuring data consistency, reducing human error, and improving overall collaboration.

By training users, configuring systems based on actual business processes, and bridging communication between technical and project stakeholders, we ensured these tools became enablers not obstacles to success.

Project Scope and Requirements

Our engagement was divided into three major service pillars:

1. SmartPlant User Training

- Conducted customized training sessions for engineering and IT personnel.

- Training covered core functionalities, real-world workflows, and integration best practices.

- Emphasized role-specific use cases across tools (e.g., how SPI data flows into S3D).

2. System Implementation & Configuration

- Set up the following Smart Enterprise tools across servers and user environments:

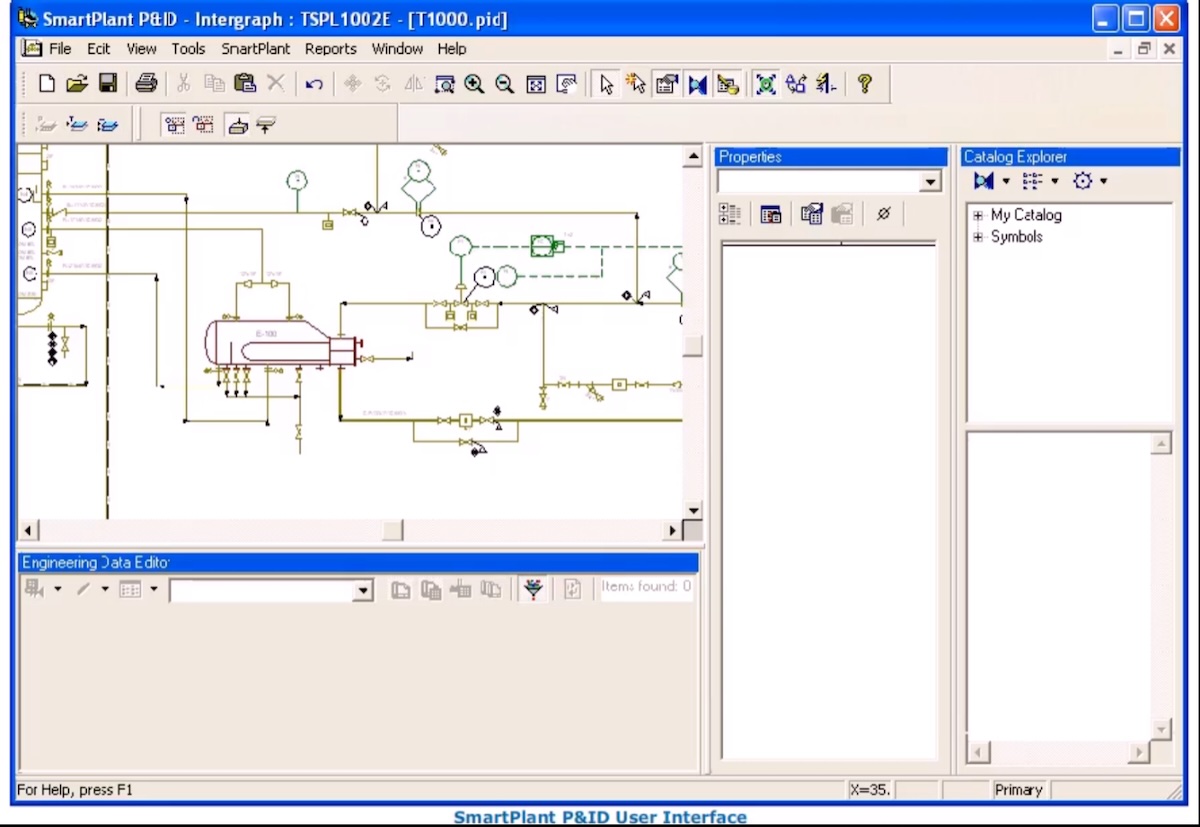

- SPPID

- SPI

- SPEL

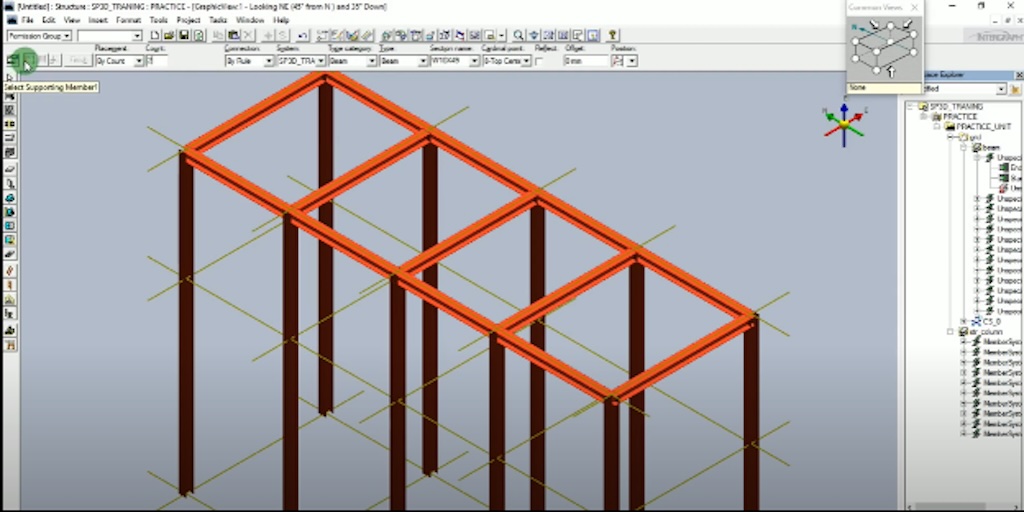

- S3D

- SSK

- SPR

- SPF

- Configuration was aligned to business processes, standards, and data governance models.

- Deployed tools on dedicated application/database servers and multiple client workstations.

3. Engineering Software Consulting

- Identified process and system gaps based on project requirements and existing workflows.

- Acted as a technical liaison with project leads and system owners.

- Provided recommendations to avoid integration issues or project delays.

- Supported risk mitigation through timely issue resolution and continuous feedback loops.

Technical Execution Framework

To ensure delivery precision and maximize value, our implementation followed this phased execution strategy:

- Assessment & Planning

-

- Performed site readiness checks and existing infrastructure evaluations.

- Outlined a deployment roadmap tailored to project timelines and user readiness.

- Installation & Deployment

-

- Installed each SmartPlant tool with the latest applicable updates and service packs.

- Set up client-server architecture for optimized performance and security.

- Custom Configuration

-

- Applied company-specific standards, schema, and templates.

- Integrated various Smart tools via SmartPlant Foundation for unified data control.

- Training & Enablement

-

- Delivered hands-on workshops for each tool.

- Provided reference manuals and role-based quick guides.

- Validation & Handover

-

- Conducted functionality tests and user acceptance trials.

- Delivered documentation, backup configuration files, and an issue resolution record.

Key Benefits of Smart Enterprise Tools

The integration of Smart Enterprise Tools into the project workflow resulted in:

- Greater Digital Maturity: Users were equipped with knowledge, not just tools.

- Improved Interdisciplinary Collaboration: Unified data models minimized design clashes and duplicated efforts.

- Risk Reduction: Early-stage gap analysis and stakeholder communication helped prevent bottlenecks.

- Sustainable Operations: Users now have a scalable, well-documented SmartPlant environment tailored for future project expansion.

Conclusion

Through comprehensive training, tailored software setup, and proactive consulting, we managed to become the digital backbone of this Raw Water Treatment Plant Project. This implementation not only supported timely project execution but also empowered engineering teams with tools and insights that will serve beyond the construction phase. Our mission continues to be clear: deliver technology with purpose, aligned with business needs, and ready for tomorrow.