In the oil and gas industry, the design of piping systems is crucial to ensuring the safe, efficient, and reliable operation of process pipelines. Oil and Gas piping design service encompass a comprehensive range of activities, from initial conceptualization to detailed engineering and installation support. These services are essential for optimizing the performance of pipelines and other piping systems, minimizing risks, and ensuring compliance with industry standards and regulations.

Type of Oil and Gas Piping Design Service:

- 2D Piping Design Service

- 3D Piping Design Service

2D Piping Design Service

In Oil and Gas Piping Design service, 2D piping design involves creating flat representations of the piping system, typically using CAD (Computer-Aided Design) software. These drawings are essential for the detailed planning and documentation of the piping system.

Key Aspects of 2D Oil and Gas Piping Design Service:

- General Arrangement and Schematics Drawings:

- Detailed blueprints that illustrate the layout, connections, and components of the piping system.

- Schematics showing the flow of fluids, including directional arrows for clear understanding of the system.

- Process and Instrumentation Diagrams (P&IDs):

- Diagrams that display the piping and related components of a process flow.

- Conversion of legacy drawings into Intelligent P&IDs.

- Project Document Links that Include information on the instruments and control devices.

- Isometric Drawings:

- 2D representations that show the three-dimensional piping layout.

- Provide details on pipe lengths, angles, and component placements.

- Bill of Materials (BOM):

- Lists all the materials, components, and equipment needed for the piping system.

- Ensures accurate procurement and inventory management.

- Detailed Engineering Drawings:

- Provide exact dimensions, specifications, and fabrication details.

- Essential for manufacturing and construction teams during the building phase.

3D Piping Design Service

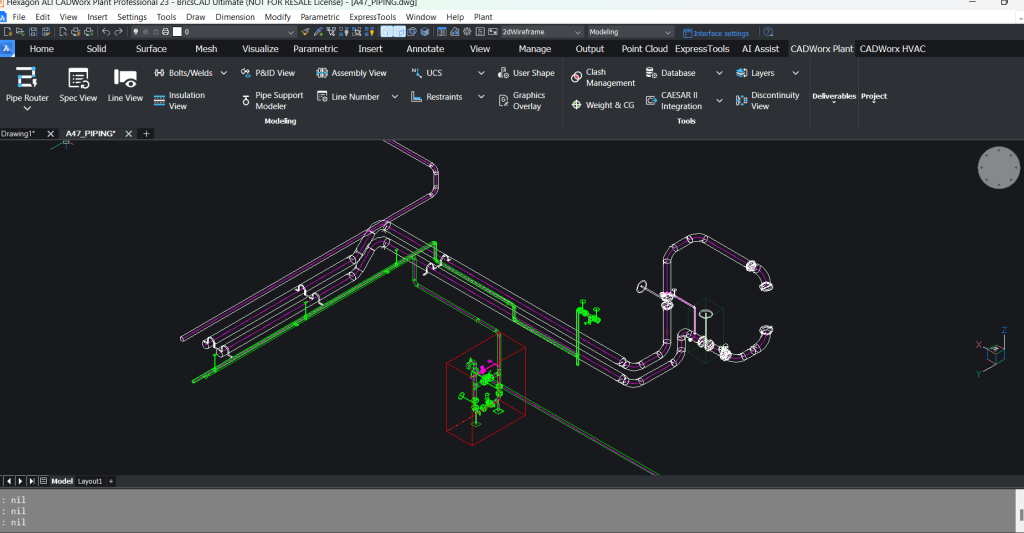

3D oil and gas piping design involve creating three-dimensional representation (Isometric Drawing) of the piping system, offering a more comprehensive and realistic view of the entire setup. This approach uses advanced software to visualize the piping layout in a virtual environment.

Key Aspects of 3D Oil and Gas Piping Design Service:

- Visual Representation:

- Realistic 3D models that provide a detailed visual representation of the piping system.

- Helps identify potential clashes and interferences with other equipment or structures.

- Spatial Planning and Optimization:

- Allows for efficient use of space by visualizing the physical layout.

- Optimizes routing and placement to reduce material costs and installation time.

- Collision and Clash Detection:

- Detects and resolves clashes between pipes, valve, structures, and other system components.

- Ensures correct orientation of piping components for better operation and maintenance accessibility.

- Simulation and Analysis:

- Simulates the operation of the piping system under various conditions.

- Analyses stress, flow, and thermal effects in the virtual environment before actual construction.

- Enhanced Documentation:

- Generates accurate and detailed isometric drawings, plans, and sections from the 3D model.

- Provides comprehensive documentation for construction, maintenance, and future modifications.

- Collaboration and Communication:

- Facilitates better collaboration among engineering, procurement, and construction teams.

- Enables stakeholders to review and comment on the design in a more interactively.

Figure 1: Example of 3D Oil and Gas Piping Design Service

Key Components of Oil and Gas Piping Design Service

- Material Selection

- Choose appropriate materials that can withstand operational conditions and are compatible with the fluids being transported.

- Consider factors such as corrosion resistance, temperature tolerance, and mechanical strength.

- Pipeline Route Selection

- Determine the optimal route for the pipeline, considering factors such as terrain, environmental impact, and accessibility.

- Conduct feasibility studies and risk assessments to identify potential challenges and mitigation measures.

- Design and Layout

- Develop detailed piping layouts, including the arrangement of pipes, fittings, valves, and other components.

- Ensure that the design facilitates efficient flow and minimizes pressure drops and turbulence.

- Stress Analysis

- Perform stress analysis to ensure that the piping system can handle the expected loads and operating conditions.

- Evaluate static and dynamic forces, including pressure, temperature, sludging, buoyance, and surge to prevent failure and ensure piping longevity.

- Support and Anchoring Systems

- Design supports, anchors, and restraints to secure the piping system and prevent movement due to thermal expansion or external forces.

- Ensure that supports are appropriately spaced and designed to handle the loads imposed by the piping system.

- Safety and Compliance

- Incorporate safety features such as pressure relief valves, emergency shutdown systems, and leak detection mechanisms.

- Ensure that the design complies with relevant industry standards and regulations, such as API, ASME, and ISO standards.

- Instrumentation and Control

- Intelligent component checking between the P&ID and 3D Models ensures full synchronization between P&ID and model components.

- Enables the linking of information or documents to P&ID components and stores this information in project databases for further processing.

- Documentation and Reporting

- Create detailed documentation, including design drawings, specifications, and calculation reports.

- Maintain accurate records for future reference, maintenance, and regulatory compliance.

- As- Built Update Support

- Provide support to update 3D model & P&ID reflect as-built conditions for better data accuracy.

- As-built data is crucial for ensuring that the finished project matches the design intent and for providing a reliable reference for future maintenance, modifications, and operations

Benefits of Professional Oil and Gas Piping Design Services

- Safety

- Proper design ensures that the piping system complies with international codes thus preventing accidents and failures.

- Ensuring proper clearances between equipment and pathways for maintenance access and emergency exits enhances operational safety.

- Efficiency

- Optimized designs lead to better flow characteristics, reduced energy consumption, and lower operational costs.

- Efficient routing and material selection minimize waste and enhance the system’s performance.

- Reliability

- Comprehensive design processes ensure that the piping system performs reliably under expected operating conditions.

- Regular maintenance and inspection are facilitated by well-documented designs.

- Cost Savings

- Professional design services help avoid costly mistakes and rework during the construction phase.

- Long-term operational costs are reduced through efficient design and material selection.

- Regulatory Compliance

- Adherence to industry standards and regulations ensures legal compliance and operational approval.

- Detailed documentation supports regulatory audits and inspections.

Conclusion

Oil and gas piping design services are essential for the safe, efficient, and reliable operation of piping systems in the industry. These services encompass a range of activities, from requirement analysis and material selection to stress analysis and installation support. By investing in professional piping design services, companies can ensure the integrity and performance of their pipelines, minimize risks, and optimize their operations for better efficiency and cost-effectiveness.

SPL Global Technologies (SPL) provides comprehensive oil and gas piping design services, leveraging both 2D and 3D design tools to deliver high-value solutions tailored to your specific needs. Our experienced engineers are committed to delivering cost-effective and reliable piping design services. For expert oil and gas piping design services, contact us at inquiry [at] spltechnologies [dot] net.