Identifying reliable and experienced professional pipe stress analysis services can be challenging due to variability in cost and the difficulty in finding high-quality service providers. SPL Global Technologies (SPL) addresses these challenges with over a decade of expertise in piping design and pipe stress analysis.

SPL boasts a team of professional engineers with extensive international project experience. Our experts deliver high-value services in piping design, pipe stress analysis, and pipe support systems. We conduct detailed stress analyses of piping systems, considering both external and functional factors.

We would like to share a notable project in pipe stress analysis conducted for a renowned oil and gas company in Malaysia. Pipe stress analysis is a critical method for evaluating the behavior of piping systems under various loading conditions. This article underscores the significance of pipe stress analysis in ensuring the safety and reliability of oil and gas operations.

In this project, we rigorously analyzed the piping system’s response to essential loads, including weight, pressures, temperatures, displacements, forces, and restraints. Our comprehensive analysis assessed the system’s flexibility, stiffness, and overall performance, providing our client with valuable insights.

Why Perform Pipe Stress Analysis? Observing Pipe Behaviors:

Pipe stress analysis involves closely monitoring the flexibility and stiffness of piping systems, enabling us to understand their responses to various operating conditions. This understanding is crucial for making informed decisions regarding the design and structural integrity of the piping system.

Determining Overstressed Pipe Designed:

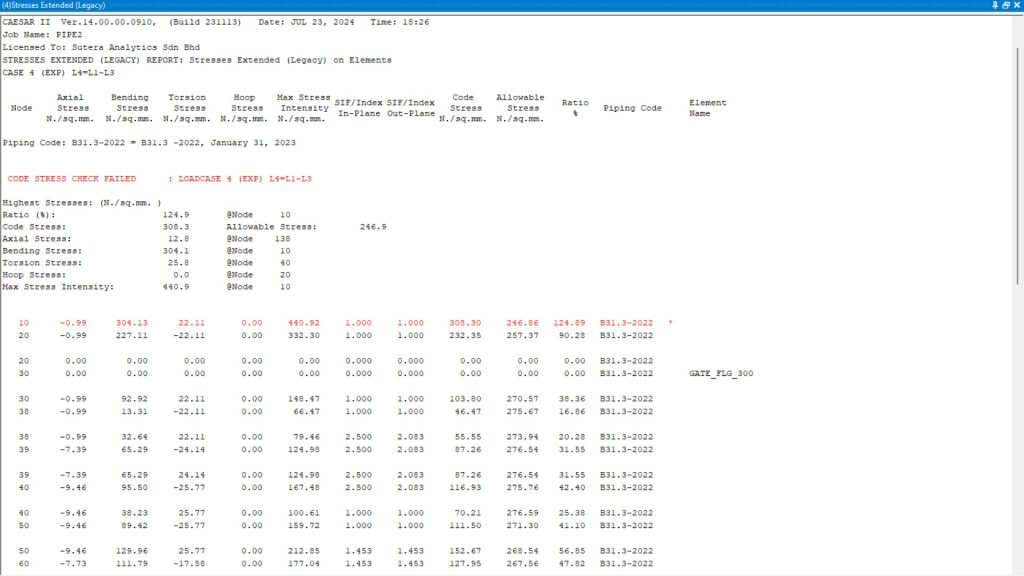

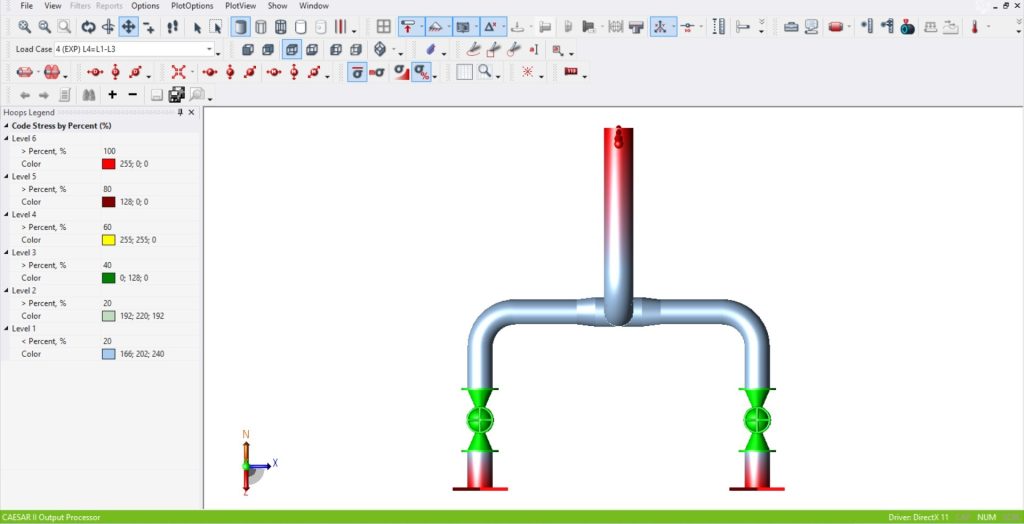

Conducting pipe stress analysis allows us to identify key parameters such as overstressed areas, maximum stresses, forces, moments, and displacements. Utilizing the advanced features of CAESAR II, our analysis results can be presented in both graphical and tabular formats, as illustrated in Figures 1 and 2. These findings are essential for pinpointing potential weak points in the piping system and ensuring compliance with applicable standards.

Figure 1: Overstressed in the piping system illustrated by red spots.

Figure 2: Red-highlighted lines indicate overstressed in the piping.

Selecting Suitable Support Systems & Pipe Support Location:

Accurate selection of support systems & pipe support placement is critical to maintaining the integrity of a piping system. Our pipe stress analysis services guide the selection of appropriate support systems that effectively handle the loads and movements of the pipes, minimizing the risk of failures.

Detecting and Preventing Issues:

Pipe stress analysis allows us to evaluate piping conditions under dynamic loads such as mechanical vibrations, seismic activity, and acoustic vibrations. This comprehensive assessment ensures that potential issues are identified and mitigated, maintaining a safe and reliable piping system operation.

Ensuring Leak-proof Systems (Flange Checks):

As part of our pipe stress analysis services, flange check calculation is crucial to help prevent leakage of hazardous mediums in pipelines that could potentially affect production, environment & safety of personnel.

With our extensive experience in pipe stress analysis service, we highlight its importance in ensuring the safety and reliability of piping systems. By conducting comprehensive analyses, we provide valuable insights into the behavior of pipes under various operating conditions. This experience reinforces the significance of pipe stress analysis in making informed decisions, mitigating risks, and ensuring smooth operations in the oil and gas industry.

We provide the following engineering services for piping, but not limited to:

- Piping Design

- Pipe Stress Analysis Service

- Pipe Support Calculation

- Pipe Stress Analysis of Oil & Gas Piping

- Piping Code

- Piping Studies and Routing, Stress Analysis

- Piping Material Specifications

- Isometrics Drawings, Stages of Material Take Off (MTO)

- Pipe Support Standards, Insulation Specifications, and Schedules

- Piping 2D/3D Modelling

- Pipe Support Detail Drawings

For a more detailed focus on Pipe Stress Analysis Service, we cover topics including but not limited to:

- Static Stress Analysis of Above Ground & Underground Lines

- Seismic & Wind Analysis

- Natural Frequency Analysis

- Analysis of Cryogenic Lines

- Analysis of Jacketed Piping

- Analysis of FRP/GRP Lines

- Stress Design Basis

- Stress Critical Line List & Stress Isometrics

- Flange Leakage Calculation

- Comprehensive Stress Report (Stress Calculation Report)

- Input to Structural Team for Support Design

If you are looking for engineering services, please contact us at +603-2300 3771 or inquiry [at] spltechnologies [dot] net for more information.