A pressure vessel is a container designed to hold gases or liquids at a pressure substantially different from ambient pressure. The construction and design of pressure vessels are crucial because they can contain substances under very high pressure, which can be dangerous if not properly managed. Understanding the fundamentals of pressure vessel design service is essential before undertaking the service.

Figure 1: Common Vertical Pressure Vessel in Plant

Common Uses of Pressure Vessels:

- Industrial Processes: Used in chemical, petrochemical, and oil & gas industries to store and process fluids and gases.

- Storage Tanks: Used to store liquefied gases like propane or ammonia.

- Reactors: Serve as reactors where chemical reactions take place under pressure.

- Heat Exchangers: Transfer heat between two or more fluids under pressure.

- Compressed Air Systems: Store and supply compressed air for various applications.

- Cryogenic Tanks: Used for the storage of cryogenic liquids that are typically liquefied gases at -150 °C or lower.

Applications Used of Pressure Vessel Design Services:

- Chemical Processing:

- Used to contain reactions and store reactants/products under controlled pressure and temperature conditions.

- Oil and Gas Industry:

- Utilized for storing and transporting crude oil, natural gas, and refined products. Also used in refining processes.

- Power Generation:

- Boilers and heat exchangers in power plants are essential for steam generation and energy transfer.

A pressure vessel design service is a specialized engineering service that focuses on the creation and development of containers designed to hold gases or liquids at a pressure significantly different from the ambient pressure. These services encompass a comprehensive range of activities aimed at ensuring the pressure vessel’s safety, reliability, and compliance with industry standards and regulations.

Key Aspects of Pressure Vessel Design Services:

- Material Selection:

- Choosing the appropriate material that can withstand internal pressure and temperature without failing. Common materials include various grades of carbon steel, stainless steel, and composite materials.

- Shape and Geometry:

- Determining the optimal shape (cylindrical, spherical, or conical) to evenly distribute stress and minimize weak points. Cylindrical shapes with rounded ends (heads) are most common.

- Wall Thickness Calculation:

- Calculating the necessary wall thickness to withstand internal pressure using formulas derived from material strength, internal pressure, and vessel diameter.

- Stress Analysis:

- Performing detailed stress analysis, including considerations for hoop stress, longitudinal stress, and radial stress, to ensure the vessel can handle the expected loads.

- Safety Features:

- Incorporating safety features like pressure relief valves, rupture discs, and safety interlocks to protect against over-pressurization.

- Support Structures:

- Designing skirt supports, saddle, and other mountings to ensure the vessel remains stable and secure during operation.

- Nozzles and Openings:

- Designing and reinforcing nozzles, manways, and other openings to ensure they do not become points of failure.

- Corrosion Allowance:

- Accounting for potential corrosion over the vessel’s life and adding extra material thickness as a corrosion allowance.

- Thermal Considerations:

- Evaluating the effects of temperature changes on material properties and design, including considerations for thermal expansion.

- Compliance with Standards and Codes:

- Ensuring the design meets applicable standards and codes, such as the ASME Pressure Vessel Code, to ensure safety and regulatory compliance.

How We Perform Pressure Vessel Design Services:

- Requirement Analysis:

- Define the vessel’s purpose, operating conditions (pressure, temperature), and the type of fluid it will contain.

- Preliminary Design:

- Develop an initial design, including basic dimensions, material selection, and preliminary calculations.

- Detailed Design and Analysis:

- Perform detailed calculations and simulations to refine the design, addressing all stress, thermal, and safety considerations.

- Review and Verification:

- Review the design for compliance with industry standards and conduct peer reviews and safety audits.

- Documentation:

- Create detailed drawings, specifications, and design reports to document the design process and decisions.

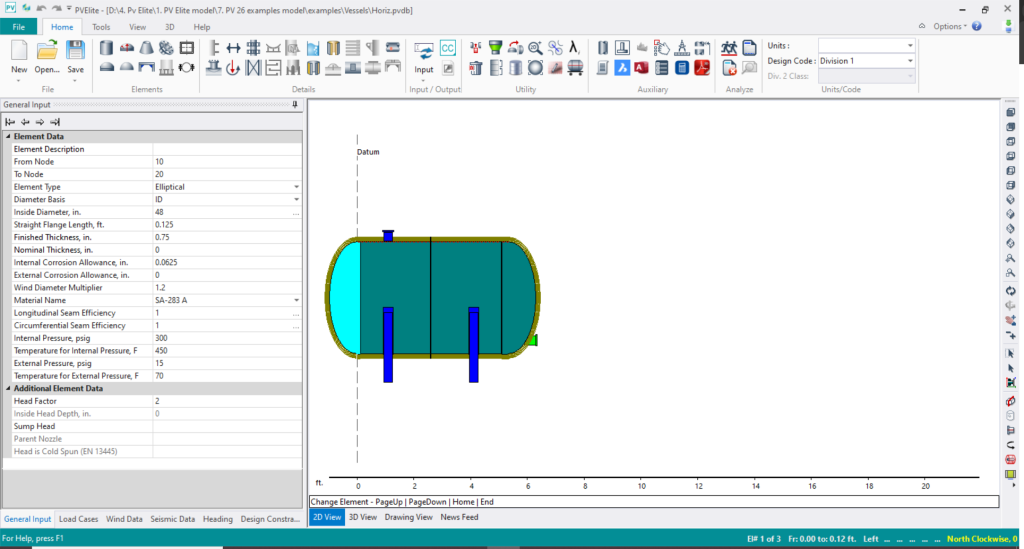

Figure 2: 2D Design of Horizontal Pressure Vessel

Why Perform Pressure Vessel Design Services:

Performing pressure vessel design services is vital to ensure the safety, efficiency, and compliance of industrial operations involving high-pressure systems. It encompasses a range of activities, from material selection and stress analysis to compliance with regulatory standards and consideration of economic factors. By investing in proper design, companies can safeguard their operations, protect their workforce, and optimize their processes for better performance and sustainability.

Here are some of the services for Mechanical Equipment design that SPL provide:

Pressure Vessel Design Service

- Pressure Vessel Stress Analysis

- Spherical Vessel Design

- Failure and Safety Analysis

- Reactor Design

- Pressure Column design and Analysis

- Horizontal and Vertical Pressure Vessels

- Fatigue Analysis as per pressure, temperature, start-up/shutdown cycles

- Component design and analysis of pressure vessels

Heat Exchanger Design Service

- Channel Covers

- Fixed tube Sheet Heat Exchangers

- Durability Analysis

- Floating Heads

- Retirement Thickness analysis

- Safety Parameter Checks

- Calculation and Analysis of Heat Equipment

- Design of Heat Exchangers as per TEMA and ASME Boiler and Pressure Vessel codes

SPL Global Technologies (SPL) has a skilled team of professional engineers with extensive international project experience spanning over a decade. Our experts deliver high-value services in pressure vessel design, analysis, evaluation, and heat exchanger design. For expert pressure vessel design services with cost-effective solutions, kindly contact us at inquiry [at] spltechnologies [dot] net.